|

|

Installing Your Fork | Before You Ride | Setting Sag | Adjusting Rebound | Locking Out the Fork | Adjusting Lockout Force | Adjusting Low-Speed Compression | Changing the Coil Spring | Service Intervals | Important Safety Information

|

|

travel |

5.5 in./140 mm |

|

features/adjustments |

low-speed compression, lockout, lockout force adjust, coil spring preload, rebound |

|

|

spring/damper type |

coil spring/FIT damper |

|

|

intended use |

all-mountain, freeride |

Be sure your fork is properly installed before proceeding. Clicking on the link above will take you to a new page.

Note: Do not use any solvents or de-greasers, as these products can cause serious damage to paint and anodized parts (upper tubes, knobs, steerers).

Do not spray water directly on the seal/upper tube junction. Do not use a high pressure washer on your fork.

You can also view a Flash video on Setting Sag.

To get the best performance from your fork, it is necessary to set and adjust sag. Generally, sag should be set to 15 – 25% of total fork travel.

FOX Part # | Approximate Spring Rate | Color Code | Travel (mm) | Rider Weight |

039-05-080 | 40.6 lb/in | Black | 140 | <90–115 |

039-05-081 | 48.5 lb/in | Purple | 140 | 115–150 |

039-05-082 | 56.4 lb/in | Blue | 140 | 150–180 |

039-05-083 | 60.9 lb/in | Green | 140 | 180–210 |

Travel | XC/Race FIRM | All-Mountain PLUSH |

80 mm (3.50") | 12 mm (0.50") | 20 mm (0.75") |

100 mm (3.90") | 15 mm (0.62") | 25 mm (0.98") |

120 mm (4.70") | 18 mm (0.69") | 30 mm (1.19") |

140 mm (5.50") | 21 mm (0.81") | 35 mm (1.38") |

150 mm (5.90") | 23 mm (0.91") | 38 mm (1.50") |

Symptom | Remedy |

Too much sag | Change to higher rate coil spring |

Too little sag | Change to lower rate coil spring |

Excessive bottoming | Change to higher rate coil spring |

Harsh ride; full travel not utilized | Change to lower rate coil spring |

The rebound adjuster knob is located at the bottom of the right fork leg, as shown in the above figure. This knob has 18 clicks of adjustment range.

Rebound controls the rate of speed at which the fork extends after compressing. Turning the knob clockwise slows down rebound; turning the knob counterclockwise speeds up rebound. As a starting point, turn the rebound adjuster knob all the way clockwise (full in) until it stops, then turn counterclockwise (out) 12 clicks.

|

Knob Setting |

Setting Description |

Tuning Tips |

Setup Tips |

|

|

Slow Rebound |

Too slow and your fork will pack down and ride harshly. |

If you increase your spring rate or air pressure, you will need to slow down your rebound |

|

12 (Factory setting) |

Average Rebound |

|

|

|

|

Fast Rebound |

Too fast and you will experience poor traction and wheel hop. |

If you decrease your spring rate or air pressure, you will need to speed up your rebound setting. |

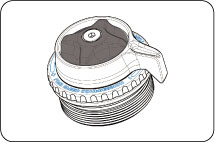

The blue compression lockout lever is located just below the black lockout force adjuster knob (see "Adjusting Lockout Force" below). It allows the rider to close the compression damping circuit in the fork. This keeps the fork at the top of its travel, making it harder to compress.

Note: When you adjust the compression lockout lever, the black lockout force adjuster knob will also move. This is normal; the lockout force adjustment setting will not be affected.

Rotate the lever fully clockwise to lockout the fork. This position is useful in climbing and sprinting situations, but will sag with the rider’s weight. The fork will "blowoff" in the event that a big hit is encountered with the fork locked out.

To unlock the fork, simply rotate the lever fully counterclockwise.

Note: The fork may cycle a couple of times after enabling lockout. Once complete lockout is achieved, the fork may continue to move 3 - 5 mm. This is normal and does not affect performance.

Even when your fork is fully locked out, there are instances when you still want your fork suspension to be active. To protect your fork's internal parts, your FOX fork will "blowoff" when it encounters an intense hit. You can adjust when the fork blows off—lockout force—with the black knob on the right-side top cap.

A convenient tuning feature of the lockout force knob is that it allows you to leave your fork in the locked out position—no more fiddling with fork controls when the trail requires your undivided attention. Although you might need to adjust the knob a few times to find the sweet spot, once it is found you can simply leave your fork locked out. Your fork will then respond to hits in the trail for example, but will be locked out when you are out of your saddle on a climb.

Turn the knob clockwise to increase lockout force and counterclockwise to decrease lockout force.

Note: When you adjust the black lockout force adjuster knob, hold the blue compression lockout lever in place.

There are 10 clicks of adjustment. As a starting point, turn the knob all the way clockwise until it stops, then back off one click counterclockwise.

Low-speed compression damping is adjusted with the blue bezel ring that is positioned just below the blue lockout lever. This ring has 8 clicks of adjustment range. Compression damping controls the fork compression speed. Adjust the low-speed compression with lockout off (the lockout lever turned fully counterclockwise). The factory setting is 8 clicks out counterclockwise, from fully in clockwise.

|

Knob Setting |

Setting Description |

Tuning Tips |

Setup Tips |

|

|

Firm Compression |

Too firm and you will experience poor traction and wheel hop. |

Resists brake dive and keeps the fork up in the travel. Too firm and you may have poor traction in loose conditions. |

|

8 |

|

|

|

|

|

Soft Compression |

Too soft and your fork will pack down and ride harsh. |

Maximum wheel traction and bump compliance. Too soft and you may have excessive brake dive and a wallowy feel. |

Note: 32 mm Vanilla forks cannot be reduced in travel.

![]()

Bushing Technology & Inspection | Seals & Foam Rings | Control Direction | Oil Volumes | Structural Inspection | Dropout Thickness Inspection | Torque Values | Unit Conversion | Suspension Tuning Tips | Using the Pump | Important Safety Information | Service Intervals | Contact FOX Service | Warranty Information | FOXHelp Service Web Site

Copyright © 2010

FOX Factory Inc.