Installing Your Fork | Before You Ride | Setting Sag | Adjusting Rebound | Adjusting High-Speed Compression | Adjusting Low-Speed Compression | Changing the Coil Spring | Changing Travel | Changing Oil | Service Intervals | Important Safety Information

|

|

weight RC2 |

6.83 lbs./3.10 kg |

|

|

8 in. / 203 mm - 6 in. / 178 mm adjustable in ½-inch increments |

|

|

features/adjustments RC2 |

internally adjustable travel, low-speed compression, high-speed compression,

hydraulic bottom-out in damper, coil spring |

|

|

features/adjustments R |

internally adjustable travel, hydraulic bottom-out in damper, coil spring preload, rebound |

|

|

spring/damper type |

titanium spring/RC2 FIT damper |

|

|

intended use |

||

|

color |

Titanium |

Be sure your fork is properly installed before proceeding. Clicking on the link above will take you to a new page.

You can also view a Flash video on Setting Sag.

To get the best performance from your fork, it is necessary

to set and adjust

|

FOX Part # |

Spring Rate |

Color Code |

Rider Weight (lbs.) |

|

039-05-070 |

30 lb/in |

Black |

< 90 – 120 |

|

039-05-071 |

35 lb/in |

Purple |

120 – 150 |

|

039-05-072 |

40 lb/in |

Blue |

150 –180 |

|

039-05-063 |

45 lb/in |

Green |

180 – 210 |

|

039-05-074 |

50 lb/in |

Yellow |

210 – > 240 |

|

Travel |

15 - 25% Sag |

|

6 in. (152mm) |

0.9 - 1.5 in. (23 - 38 mm) |

|

6.5 in. (165mm) |

1.0 - 1.6 in. (25 - 41 mm) |

|

7 in. (178mm) |

1.1 - 1.8 in. (27 - 45 mm) |

|

7.5 in. (191mm) |

1.1 - 1.9 in. (29 - 48 mm) |

|

8 in. (203mm) |

1.2 - 2.0 in. (30 - 51 mm) |

|

Symptom |

Remedy |

|

Too much sag |

Change to higher rate coil spring |

|

Too little sag |

Change to lower rate coil spring |

|

Excessive bottoming |

Change to higher rate coil spring |

|

Harsh ride; full travel not utilized |

Change to lower rate coil spring |

The rebound knob (shown below) is located on the top of the right fork leg, and has 15 clicks of adjustment. Rebound controls the speed at which the fork extends after compressing. Turning the knob clockwise slows down rebound; turning the knob counterclockwise speeds up rebound. As a starting point, turn the rebound adjuster knob all the way clockwise (full in) until it stops, then turn counterclockwise (out) 8 clicks.

|

Knob Setting |

Setting Description |

Tuning Tips |

Setup Tips |

|

|

Slow Rebound |

Too slow and your fork will pack down and ride harsh. |

If you increase your spring rate or air pressure, you will need to slow down your rebound |

|

8 (Factory setting) |

Average Rebound |

|

|

|

|

Fast Rebound |

Too fast and you will experience poor traction and wheel hop. |

If you decrease your spring rate or air pressure, you will need to speed up your rebound setting. |

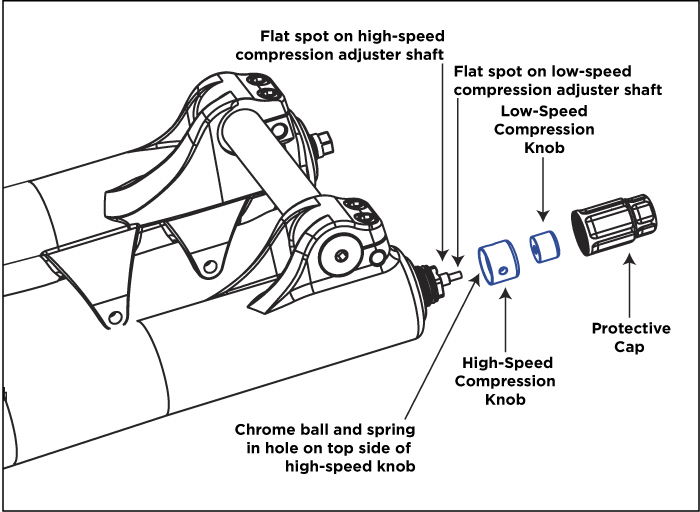

High-speed

|

Knob Setting |

Setting Description |

Tuning Tips |

|

|

Soft Compression |

Maximum wheel traction and bump compliance. If setting is too soft, you may bottom often on square-edged hits and G-outs. |

|

1 (Factory setting) |

Average Compression |

|

|

|

Firm Compression |

Reduces bottom-out and provides maximum bump absorption. If setting is too firm, you may experience a harsh ride with bad traction and use too little available travel. |

The high-speed compression adjuster is equipped with a maximum “Boost” setting. This setting offers increased bump force resistance well beyond the adjuster's linear range up until the stop at full firm (clockwise). To enable the “Boost” feature, turn the high-speed compression knob to the full in (clockwise) position, to the stop with firm hand torque. You can use a 3mm hex key to assist in turning the knob to the full in position or to help turn the knob out to Minimum high speed setting.

Low-speed compression damping controls the influence of the rider’s weight shifts and bike attitude under braking. This adjuster rotates to stops at each end and has 17 clicks of adjustment. It is preset from the factory at 1 click in from the full out (counterclockwise) position. The knob is protected by the black protective cap. Never ride your FOX 36 without the black protective cap.

|

Knob Setting |

Setting Description |

Tuning Tips |

|

|

Soft Compression |

Maximum wheel traction and bump compliance. Too soft and you maybe have excessive brake dive and wallowy feel. |

|

1 (Factory setting) |

Average Compression |

|

|

|

Firm Compression |

Resists brake dive and keeps the fork up in the travel. Too firm and you may have poor traction in loose conditions. |

The 40 is equipped with a patent-pending Internally Adjustable Hydraulic Bottom-Out Control System. This feature can be adjusted inside the cartridge by FOX Racing Shox or an Authorized Service Center. It comes preset from the factory at the FIRM setting.

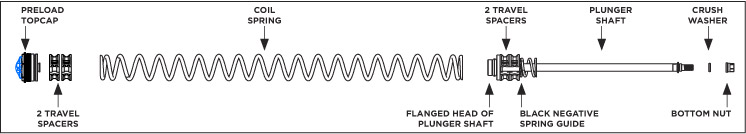

Travel on the 40 can be changed from 8” to 6” in 1/2” increments by rearranging the four internal travel spacers inside the left leg of the fork. With the proper tools and oil, changing travel can be done in about 15 minutes.

The following tools and supplies will be needed: A 32mm 6-point socket, 10mm open end wrench or socket, torque wrench, plastic hammer, oil drain pan, clean dry lint-free towels, measuring container, as well as the following:

|

Quantity |

Part Number |

Part Name |

|

1 |

025-03-004-A |

1 qt. bottle of Fox Suspension Fluid (7 wt.) |

|

Travel Setting |

# of Spacers Under Topcap |

# of Spacers on Plunger Shaft |

|

8.0" (203mm) |

4 |

0 |

|

7.5" (190mm) |

3 |

1 |

|

7.0" (178mm) |

2 |

2 |

|

6.5" (165mm) |

1 |

3 |

|

6.0" (152mm) |

0 |

4 |

The following tools and supplies will be needed: A 32mm 6-point socket, 10mm open end wrench or socket, 15mm deep 6-point socket, torque wrench, 2mm hex key wrench (RC2 only), plastic hammer, small screwdriver, oil drain pan, clean dry lint-free towels, as well as the following:

|

Quantity |

Part Number |

Part Name |

|

1 |

025-03-004-A |

1 qt. bottle of Fox Suspension Fluid (7 wt.) |

|

1 |

241-01-002-C |

8mm Crush washer |

|

1 |

241-01-011 |

13mm Crush Washer |

Oil change on the FOX 40 RC2 or R fork consists of changing the lower leg oil bath in each leg. This oil bath service can be performed with the common tools listed above, and the fork does not have to be removed from the bicycle. This service will not require any disassembly of the closed RC2 or R cartridge.

Do not attempt to disassemble the FOX 40 RC2 or R Closed Cartridge System. Only FOX Racing Shox or an Authorized Service Center should perform such a procedure.

The 1/8” diameter chrome steel detent ball and detent spring are in the machined hole in the high-speed compression adjuster knob.

eng043

![]()

Bushing Technology & Inspection | Seals & Foam Rings | Seal Cleaning | Control Direction | Oil Volumes | Structural Inspection | Dropout Thickness Inspection | Torque Values| Unit Conversion | Suspension Tuning Tips | Using the Pump | Important Safety Information | Service Intervals | Contact FOX Service | Warranty Information